Magnesium for Die-Casting & Advanced Manufacturing

Material solutions supporting precision casting, machining, and high-performance automated production systems

Advanced die-casting and automated production environments require materials and processes that support accuracy, repeatability, and efficient high-volume manufacturing.

Engineering Demands of Precision Manufacturing

Dimensional Accuracy

Precision casting and machining processes depend on materials that support tight tolerances and consistent part geometry.

Process Stability

Reliable production requires materials that behave predictably across repeated casting and machining cycles.

MProduction Efficiency

High-volume manufacturing environments depend on materials that support efficient cycle times and streamlined workflows.

Automation Compatibility

Modern production systems integrate robotics and automated handling, requiring materials suitable for controlled, repeatable processing.

Production & Process Applications

Magnesium supports a range of casting and manufacturing processes where precision, repeatability, and production efficiency are essential.

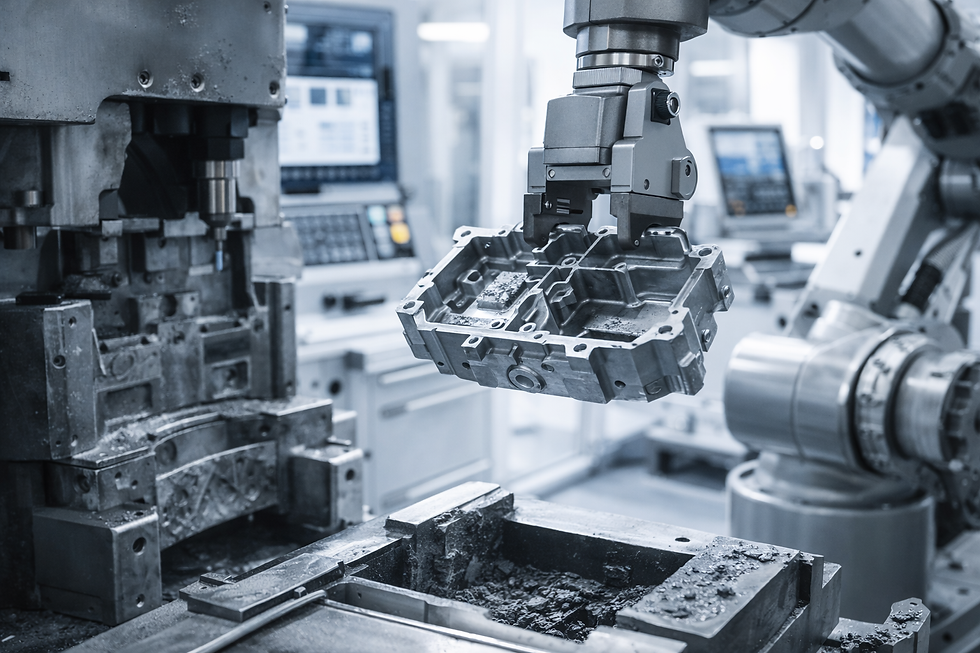

High-Pressure Die-Casting

Magnesium feedstock is used in precision die-casting processes that produce complex, lightweight components for industrial applications.

Precision Machining Operations

Cast magnesium parts are commonly machined to achieve tight tolerances and refined surface finishes required in advanced production.

Tooling & Mold Production

Magnesium is used in applications where lightweight tooling components and support structures are beneficial within manufacturing environments.

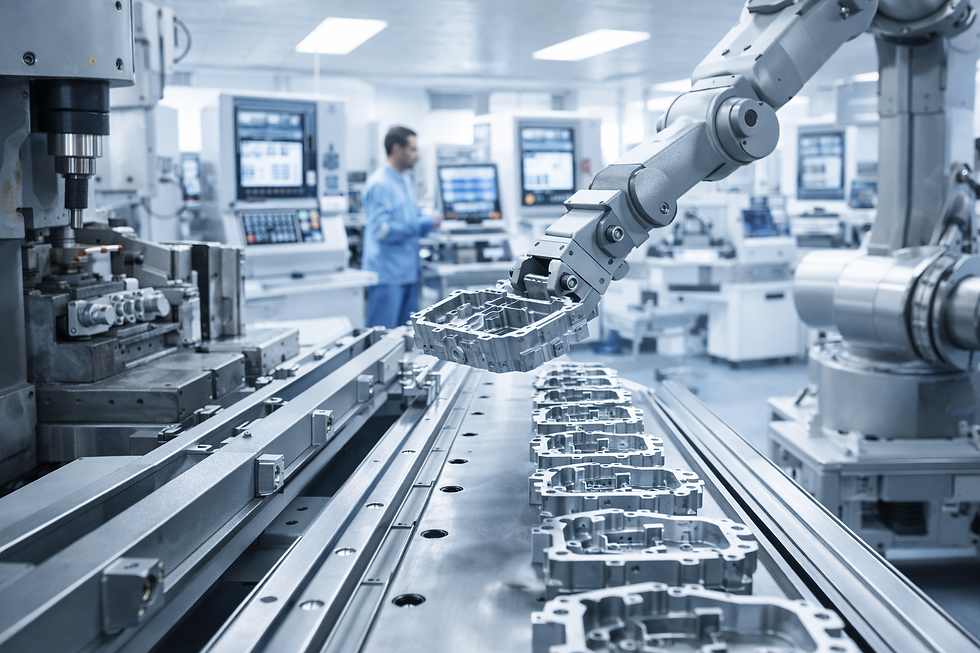

Automated Handling & Production Cells

Magnesium components move efficiently through robotic handling, automated transfer systems, and integrated production lines.

Component Finishing & Assembly

Post-casting processes such as trimming, machining, and surface finishing prepare parts for integration into broader manufacturing systems.

In advanced manufacturing environments, material performance begins at the process level — where precision casting, controlled machining, and automated production define component quality.